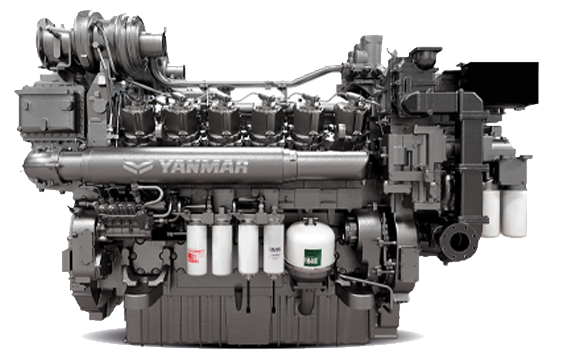

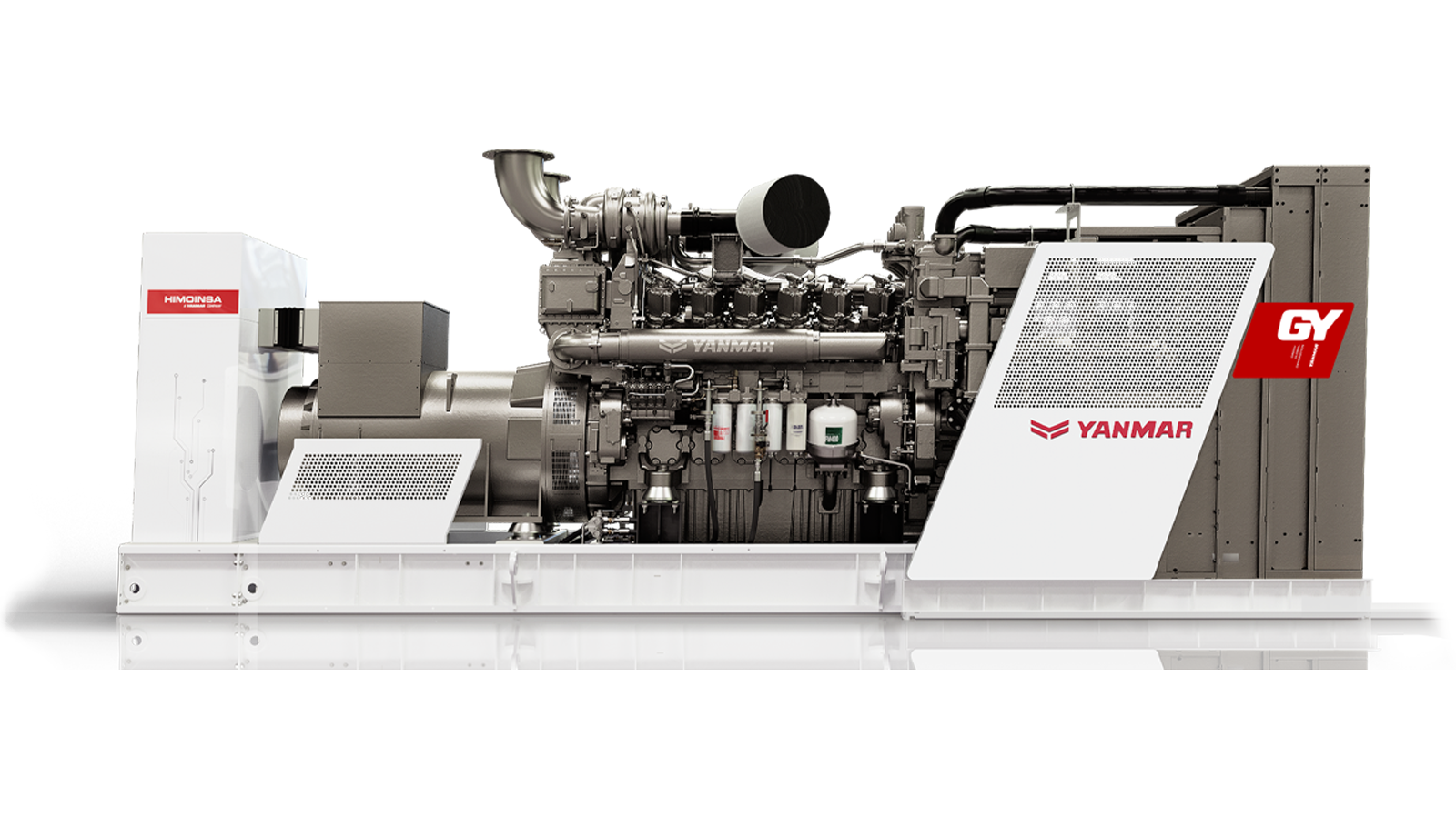

HIMOINSA launches HGY Series; new generators up to 3500kVA with Yanmar engine for critical power supply

June 24, 2024

Modelo 02

June 24, 2024

HIMOINSA launches HGY Series; new generators up to 3500kVA with Yanmar engine for critical power supply

June 24, 2024

Modelo 02

June 24, 2024

GY2000T5

Tincidunt mauris

Integer aliquam

Malesuada fames

Bibendum sapien

Mollis consequat eleifend.

Aliquam sagittis ligula at magna ullamcorper rhoncus. Duis fringilla magna non quam tincidunt porttitor. Duis orci sapien, tempus auctor euismod quis, pulvinar at magna. Proin a velit massa. Pellentesque nec dolor sollicitudin, consectetur tellus sit amet, semper enim. Nunc quis iaculis massa. Integer non elementum orci, in eleifend libero. Mauris ut urna pulvinar dui ultrices hendrerit. Cras malesuada neque eu risus auctor, vitae auctor lorem accumsan

Nunc quis iaculis massa

Integer non elementum orci, in eleifend libero. Mauris ut urna pulvinar dui ultrices hendrerit. Cras malesuada neque eu risus auctor, vitae auctor lorem accumsan Aliquam sagittis ligula at magna ullamcorper rhoncus. Duis fringilla magna non quam tincidunt porttitor. Duis orci sapien, tempus auctor euismod quis, pulvinar at magna. Proin a velit massa. Pellentesque nec dolor sollicitudin, consectetur tellus sit amet, semper enim.